BioShakti and Renergon are implementing Dry Anaerobic Digestion Technology to Reduce Methane Emissions. The commercial production will begin in early 2021.

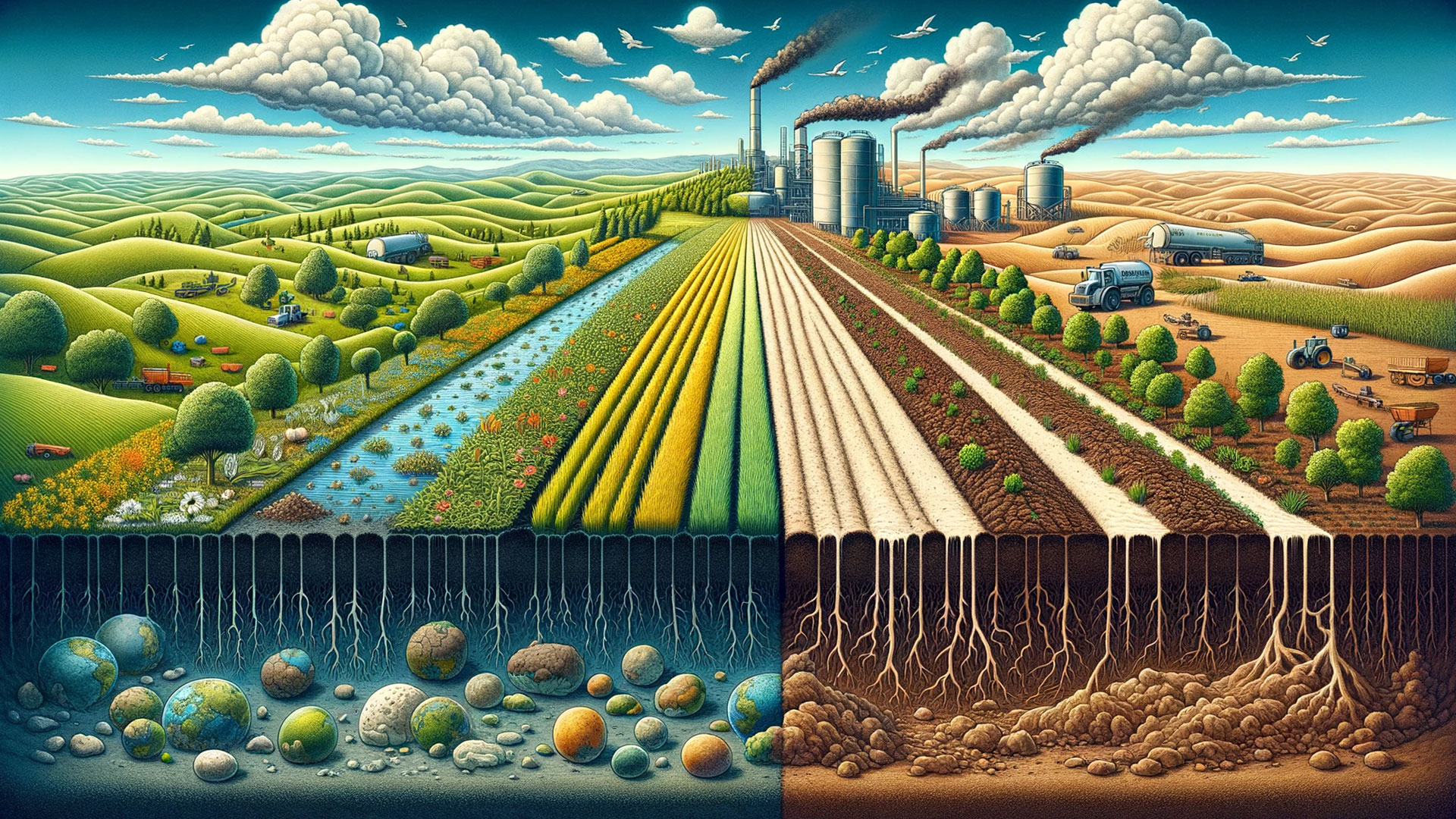

Using funding from a Renewable Energy & Promotion in International Cooperation (REPIC) grant awarded by the Swiss federal government, BioShakti (India) is collaborating with Renergon (Switzerland) to introduce the use of dry anaerobic digestion in the city of Patiala in Punjab, India. Over the past decade, the highest rate of rice straw burning in India has occurred in the state of Punjab, leading to significant atmospheric releases of methane and other greenhouse gasses. The substantial quantity of rice straw that is available in Punjab, along with its extensive dairy industry, makes it an excellent candidate for implementing dry anaerobic digestion technology to reduce methane emissions.

Waste Plant to Produce CNG and Composts

Development is underway on a solid waste fermentation plant near the city of Patiala in southeastern Punjab that will co-treat cattle manure and rice straw. Renergon’s solid waste fermentation system (dry digestion in fermenter boxes) does not require the use of a mixable and pumpable substrate liquid blend, which greatly minimizes the need for water when organic waste is utilized. Including rice straw in the fermentation system eliminates the burning of straw in the fields and ensures a huge improvement in air quality. The biogas produced from the system will be processed and treated into compressed natural gas (bio-CNG) and stored in gas cylinders. Additionally, a multi-nutrient and humus fertilizer will be produced as marketable composts.

Anticipated emission reductions from implementing the dry anaerobic digestion technology include approximately 792 tons per year of CO2e reduced by eliminating the burning of crop residue and manure management activities, and 2,700 tons per year of CO2e reduced by replacing the use of fossil fuels with the produced bio-CNG. Commercial production will begin in early 2021.